Automatic Bag Slitting Machine

Bag Slitting Machine Description

Automatic Bag Slitting Machine is used for slitting and emptying of single or multiple layer bags made from paper, poly-ethylene, poly-ethylenelined paper, interwoven plastic, or poly-ethylene-lined interwoven plastic. Dynemix India is a leading manufacturer, exporter and supplier of Bag Slitting Machine which is made up of a splitting unit which consists of a trough that encloses an extra heavy-duty splitting Cutter Unit, complete with an appropriate gear motor and a screening unit that consists of a horizontal, cylindrically shaped rotating screen, Bag Tranter Conveyor complete with drive unit. On top of the screening unit a suitable fan-operated dust collector can be integrated for powder material. Alternatively, the Bag Slitting Machine is supplied with connecting spigots for a central de-dusting unit

Dynemix Bag Slitting Machine: Enhancing Efficiency in Material Handling

Streamlined Bag Processing

The Dynemix Bag Slitting Machine revolutionizes bag handling, offering a comprehensive system designed for seamless material processing. Its multifaceted design integrates a series of components, ensuring optimal functionality and efficiency.

Bag Slitting Machine Comprises of:

- Bag Feeding Conveyor: Enables smooth and continuous input of bags for processing.

- Bag Cutting Unit with Roller-Guide: Precision cutting mechanism to slit bags swiftly and accurately.

- Bag Emptying Machine: Facilitates efficient emptying of bag contents, minimizing waste and maximizing productivity.

- Built-in Dust Extraction System: Specifically crafted for powder material, ensuring a clean and safe working environment.

- Empty Bag Compactor: Compact and condense empty bags, optimizing storage space and waste management.

- Unloaded Material Storage Hopper: Provides a dedicated space for storing processed material, ensuring organized workflow.

- Optional Pneumatic Conveying System: Offers flexibility for material transport, if required.

Superior Performance and Adaptability

The holistic design of the Dynemix Bag Slitting Machine guarantees superior performance across various industries. Its adaptable nature caters to different material types and operational needs, enhancing overall productivity while reducing manual effort.

Crafted with precision engineering, this machine amalgamates cutting-edge technology with user-friendly controls, ensuring ease of operation and maintenance. The robust construction ensures durability, promising longevity and sustained high performance.

Redefining Material Handling Efficiency

The Dynemix Bag Slitting Machine is a solution-driven system. From enhancing workflow efficiency to maintaining stringent safety standards, this machine stands as a testament to innovation in material handling technology. Whether in manufacturing, packaging, or logistics, its versatile capabilities elevate operational excellence while ensuring a hassle-free bag processing experience.

Unleash the potential of streamlined bag processing with the Dynemix Bag Slitting Machine - where efficiency meets innovation.

Bag Slitting Machine Salient Features:

- Material: Carbon Steel, 304L / 316L stainless steel

- Compact, robust design

- Available with dust collector or equipped for centralised de-dusting system

- Machine consists of a small number of components (only few spare parts required)

- Easy access to all machine parts

- Low operating noise level

- Easy and quick replacement of filter elements

- Able to handle bags of different sizes without machine adjustment

- Low product residue

- The system can be supplied in modular form.

- Capacity UP TO 30 TPH

- Reduce Labour Cost

- Totally dust free operation.

- Easy handling of empty bags. (Provided Bag Compactor)

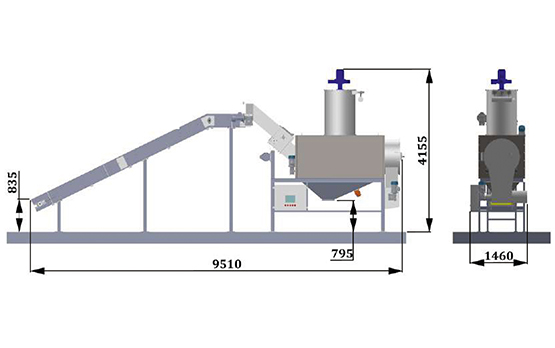

- Space required - 9.5m x 1.5m x 4.2m

- Power requirement – 16.10 HP approx. (Sequence operation). (with conveyor/machine proper/DE system/empty bag compactor).

Drawing: