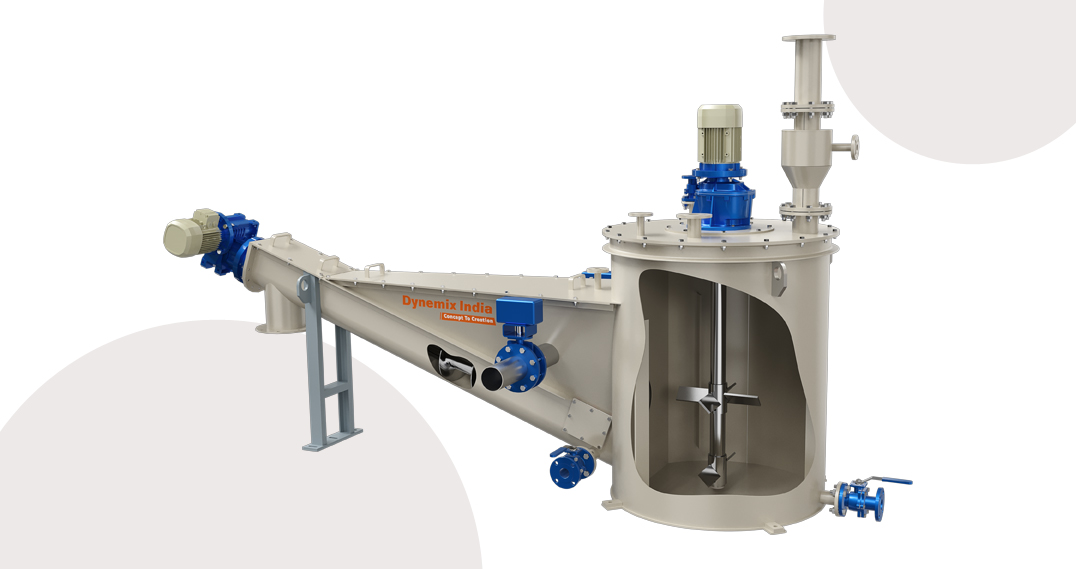

Lime Slaker

Lime Slaker Description:

For industries requiring substantial amounts of lime slurry, a cost-effective approach involves on-site slaking of quick lime. This entails injecting quick lime into an agitated slaking tank, maintaining a high concentration. The exothermic reaction, triggered by the combination of quick lime and water, generates heat and steam.

To manage excess steam, a dust scrubber positioned atop the tank ensures proper tank aeration. The automated process is secured through a temperature probe, electronic flowmeter, and ultrasonic level probe. Once quick lime is slaked, the resulting lime slurry overflows into a dilution tank, where water is added to achieve the desired final concentration for pumping.

In contrast, some processes require a simpler approach without the need for high-quality lime slurry. Batch slakers, also known as mix tanks, produce a precisely metered slurry and are ideal for applications with relatively low slurry production rates and minimal changes to quicklime quality and water sources.

Batch slakers suit applications with low usage that don't demand high-quality lime slurry or where a continuous flow of lime slurry is needed for downstream processes. They are particularly effective in scenarios with a consistent source of both quicklime and water. This makes them suitable for applications where a relatively constant and small amount of hydrated lime slurry is required daily, and where cost or supply considerations preclude the use of hydrate or pre-made lime slurry solutions. In such instances, a batch slaker emerges as the most economical and practical solution available.

Dynemix is a leading manufacturer, exporter and wholesale supplier of lime slaker and specializes in customizing batch type slacker/mix tanks with various options tailored to your specific needs. Let Dynemix assess your requirements to determine the optimal fit for your application.

We would be delighted to speak with you personally about the many options for precisely fine-tuning your production processes. We look forward to your enquiry!