Automatic Bag Stitching and Conveying System

- Client: UPL Limited (UPL-1)

- Supply: Automatic Bag Stitching and Conveying System

- Material: CaCl2 Bags

- Location: Ankleshwar, Gujarat

Description of Supply:

- Bag Conveying System is a combination of different Belt Conveyors with Compatible attachments and spacing.

- All the conveyors are having a separate Motor Gearbox Drives.

- Empty bags are placed at the first conveyor and it is a mounted on Load cell. One Weighing Indicator with Cabinet is placed at eyesight level to read the weight reading of bag.

- After completion of filling, the bag is transferred further and flipped from vertical to horizontal orientation by means of a Special Attached Mechanism

- In the length of conveyor there is one Bag Counting sensor is provided to maintain the production record

- After this, filled bag will stitch by an Automatic Bag Stitching Machine and the conveyor further moves the bag towards the application.

- Bag Cleaning Rolls are equipped with the smooth brushes to clean the bag from outside

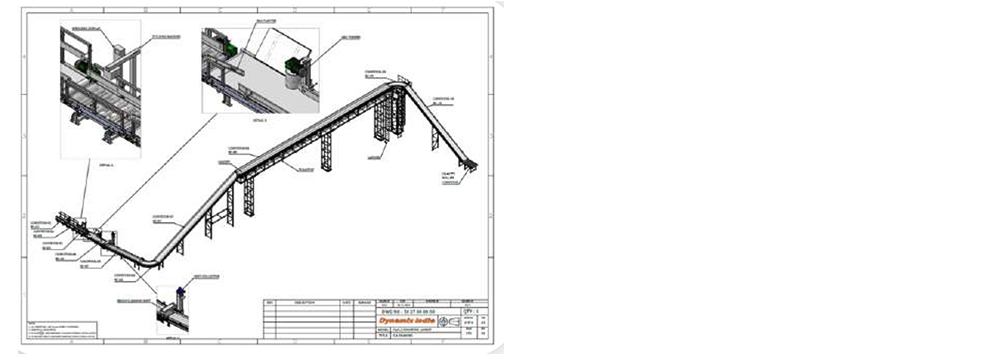

Drawing:

Equipment / Instruments use for Automatic Bag Stitching and Conveying System:

- Belt Conveyors of Customised Lengths and Drives

- Bag Guide Flappers in all Conveyors

- Bag Turner

- Bag Counte

- Automatic Bag Stitching Machine

- Bag Cleaning Roll Brush

- Dust Collector

- Steel Structure and Supports

- Walk Ways and Ladders

- Radial Belt Conveyor

- Decline Belt Conveyor

- Roller Belt Conveyor